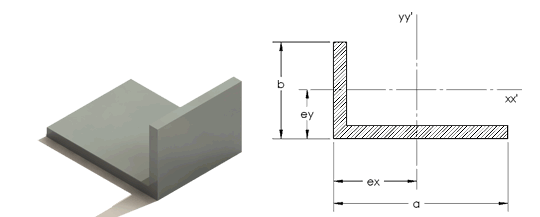

Angles

There is a minimum quantity of production from each die

Very small quantities can be produced only according to a special price list or after special agreement .

SPECIFICATIONS

|

a (mm) |

b (mm) |

t (mm) |

Area (mm2) |

Th. Weight (gr/m) |

Th. Weight 6m (kgr) |

ey (mm) |

ex (mm) |

Éxx (cm^4) |

Éyy (cm^4) |

Éxy (cm^4) |

Sx (cm^3) | Sy (cm^3) |

É1 (cm^4) |

É2 (cm^4) |

È (degrees) | i1 (cm) | i2 (cm) |

| 10 | 10 | 1 | 19 | 51 | 0.3 | 7.13 | 2.87 | 0.01800 | 0.01800 | 0.01066 | 0.02524 | 0.02524 | 0.0287 | 0.0073 | 0.0000 | 0.3884 | 0.1966 |

| 10 | 10 | 1.4 | 26 | 70 | 0.4 | 6.99 | 3.01 | 0.02383 | 0.02383 | 0.01392 | 0.03410 | 0.03410 | 0.0377 | 0.0099 | -45.0000 | 0.3807 | 0.1951 |

| 15 | 15 | 1 | 29 | 78 | 0.5 | 10.88 | 4.12 | 0.06372 | 0.06372 | 0.03802 | 0.05857 | 0.05857 | 0.1017 | 0.0257 | 0.0000 | 0.5923 | 0.2977 |

| 15 | 15 | 1.2 | 35 | 93 | 0.6 | 10.81 | 4.19 | 0.07501 | 0.07501 | 0.04463 | 0.06942 | 0.06942 | 0.1196 | 0.0304 | 0.0000 | 0.5884 | 0.2965 |

| 15 | 15 | 1.6 | 45 | 123 | 0.7 | 10.66 | 4.34 | 0.09629 | 0.09629 | 0.05690 | 0.09032 | 0.09032 | 0.1532 | 0.0394 | 45.0000 | 0.5806 | 0.2944 |

| 20 | 20 | 39 | 105 | 0.6 | 14.63 | 5.37 | 0.15476 | 0.15476 | 0.09256 | 0.10580 | 0.10580 | 0.2473 | 0.0622 | 0.0000 | 0.7963 | 0.3993 | |

| 20 | 20 | 1.4 | 54 | 146 | 0.9 | 14.48 | 5.52 | 0.21045 | 0.21045 | 0.12548 | 0.14533 | 0.14533 | 0.3359 | 0.0850 | 45.0000 | 0.7884 | 0.3965 |

| 22 | 11 | 1.2 | 38 | 103 | 0.6 | 8.71 | 7.79 | 0.03434 | 0.19462 | 0.04654 | 0.03945 | 0.13701 | 0.2072 | 0.0218 | 15.0719 | 0.7368 | 0.2391 |

| 25 | 15 | 1 | 39 | 105 | 0.6 | 11.81 | 8.19 | 0.07356 | 0.25956 | 0.08077 | 0.06229 | 0.15443 | 0.2897 | 0.0434 | 20.4869 | 0.8619 | 0.3335 |

| 25 | 25 | 1.2 | 59 | 158 | 0.9 | 18.30 | 6.70 | 0.36378 | 0.36378 | 0.21764 | 0.19875 | 0.19875 | 0.5814 | 0.1461 | 0.0000 | 0.9964 | 0.4996 |

| 25 | 25 | 1.5 | 73 | 196 | 1.2 | 18.19 | 6.81 | 0.44683 | 0.44683 | 0.26687 | 0.24560 | 0.24560 | 0.7137 | 0.1800 | 0.0000 | 0.9905 | 0.4974 |

| 30 | 8 | 1.4 | 51 | 138 | 0.8 | 6.58 | 12.42 | 0.01616 | 0.47003 | 0.04332 | 0.02456 | 0.26738 | 0.4741 | 0.0121 | 5.4039 | 0.9619 | 0.1534 |

| 30 | 20 | 1.5 | 73 | 196 | 1.2 | 15.44 | 9.56 | 0.25164 | 0.68658 | 0.24460 | 0.16303 | 0.33597 | 0.7964 | 0.1418 | 24.1802 | 1.0463 | 0.4415 |

| 30 | 1.4 | 82 | 222 | 1.3 | 21.98 | 8.02 | 0.73482 | 0.73482 | 0.43969 | 0.33433 | 0.33433 | 1.1745 | 0.2951 | 45.0000 | 1.1965 | 0.5998 | |

| 30 | 30 | 1.7 | 99 | 268 | 1.6 | 21.87 | 8.13 | 0.87934 | 0.87934 | 0.52546 | 0.40210 | 0.40210 | 1.4048 | 0.3539 | 0.0000 | 1.1905 | 0.5975 |

| 30 | 30 | 2 | 116 | 313 | 1.9 | 21.76 | 8.24 | 1.01959 | 1.01959 | 0.60828 | 0.46859 | 0.46859 | 1.6279 | 0.4113 | 0.0000 | 1.1846 | 0.5955 |

| 30 | 30 | 2.5 | 144 | 388 | 2.3 | 21.58 | 8.42 | 1.24424 | 1.24424 | 0.73981 | 0.57668 | 0.57668 | 1.9840 | 0.5044 | 0.0000 | 1.1748 | 0.5924 |

| 34.2 | 16.2 | 1.2 | 59 | 159 | 1.0 | 13.13 | 12.07 | 0.11633 | 0.74088 | 0.16723 | 0.08860 | 0.33478 | 0.7828 | 0.0744 | 14.0848 | 1.1515 | 0.3549 |

| 35 | 20 | 2 | 106 | 286 | 1.7 | 15.60 | 11.90 | 0.33727 | 1.36302 | 0.39226 | 0.21615 | 0.58996 | 1.4958 | 0.2045 | 18.7050 | 1.1879 | 0.4392 |

| 35 | 35 | 2.5 | 169 | 456 | 2.7 | 25.32 | 9.68 | 2.00995 | 2.00995 | 1.19806 | 0.79369 | 0.79369 | 3.2080 | 0.8119 | 0.0000 | 1.3788 | 0.6936 |

| 35 | 35 | 3 | 201 | 543 | 3.3 | 25.14 | 9.86 | 2.36290 | 2.36290 | 1.40418 | 0.93983 | 0.93983 | 3.7671 | 0.9587 | 0.0000 | 1.3690 | 0.6906 |

| 35 | 5 | 325 | 878 | 5.3 | 24.42 | 10.58 | 3.63502 | 3.63502 | 2.12019 | 1.48835 | 1.48835 | 5.7552 | 1.5148 | 45.0000 | 1.3307 | 0.6827 | |

| 40 | 25 | 1 | 64 | 173 | 1.0 | 19.81 | 12.69 | 0.34991 | 1.10391 | 0.36563 | 0.17661 | 0.40418 | 1.2521 | 0.2017 | 22.0612 | 1.3987 | 0.5614 |

| 40 | 40 | 1.2 | 95 | 255 | 1.5 | 29.55 | 10.45 | 1.53007 | 1.53007 | 0.91702 | 0.51775 | 0.51775 | 2.4471 | 0.6130 | -45.0000 | 1.6087 | 0.8052 |

| 40 | 40 | 3 | 231 | 624 | 3.7 | 28.89 | 11.11 | 3.58182 | 3.58182 | 2.13351 | 1.23983 | 1.23983 | 5.7153 | 1.4483 | 0.0000 | 1.5729 | 0.7918 |

| 40 | 40 | 3.5 | 268 | 723 | 4.3 | 28.71 | 11.29 | 4.10448 | 4.10448 | 2.43810 | 1.42976 | 1.42976 | 6.5426 | 1.6664 | 45.0000 | 1.5632 | 0.7889 |

| 40 | 40 | 4 | 304 | 821 | 4.9 | 28.53 | 11.47 | 4.60811 | 4.60811 | 2.72842 | 1.61539 | 1.61539 | 7.3365 | 1.8797 | 0.0000 | 1.5535 | 0.7863 |

| 50 | 15 | 1.3 | 83 | 224 | 1.3 | 12.74 | 19.76 | 0.10741 | 2.18330 | 0.25530 | 0.08433 | 0.72206 | 2.2142 | 0.0765 | 6.9093 | 1.6352 | 0.3039 |

| 60 | 60 | 6 | 684 | 1,847 | 11.1 | 42.79 | 17.21 | 23.32857 | 23.32857 | 13.81263 | 5.45194 | 5.45194 | 37.1412 | 9.5159 | 45.0000 | 2.3302 | 1.1795 |

| 80 | 80 | 2.2 | 347 | 937 | 5.6 | 59.18 | 20.82 | 22.52417 | 22.52417 | 13.50190 | 3.80612 | 3.80612 | 36.0261 | 9.0223 | -45.0000 | 3.2214 | 1.6121 |

|

All the calculated data in the above table, is based on the theoritical dimensions of the profiles. Tolerances compy with EN 755. If stricter tolerances are required, then they have to be confirmed with the sales department. |

|||||||||||||||||

|

Ôá óôïé÷åßá ãéá ôéò äéáôïìÝò ðïõ ðåñéÝ÷åé ï ðßíáêáò, õðïëïãßóèçêáí âÜóåé ôùí èåùñçôéêþí äéáóôÜóåùí ôùí äéáôïìþí. Ïé äéáôïìÝò Ý÷ïõí áíï÷Ýò äéáóôÜóåùí êáé ìïñöÞò âÜóåé ôïõ EN 755. Áí ðñüêåéôáé íá ÷ñçóéìïðïéÞóåôå ôá ðñïößë óå åéäéêÝò åöáñìïãÝò, ðïõ áðáéôïýí êáé áõóôçñüôåñåò áíï÷Ýò, ðñÝðåé íá ôï áíáöÝñåôáé óôçí ðáñáããåëßá óáò. |

|||||||||||||||||

|

Notes: t: thickness ex, ey: Position of the neutral axis Ixx, Iyy: moment of inertia with respect on x, y axis accordingly. Ixy: product of inertia Sx, Sy: section modulus with respect on x, y axis respectively, I1, I2: major moment of inertia i1, i2: radii of gyration with respect on major axis respectively è: major system (degrees) (clockwise rotation) PSM: Plastic Section Moduli, (cm3) It: Torsional Constant (cm4) |

|||||||||||||||||